ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreTop 5 Benefits of Stainless Steel Woven Wire Mesh?

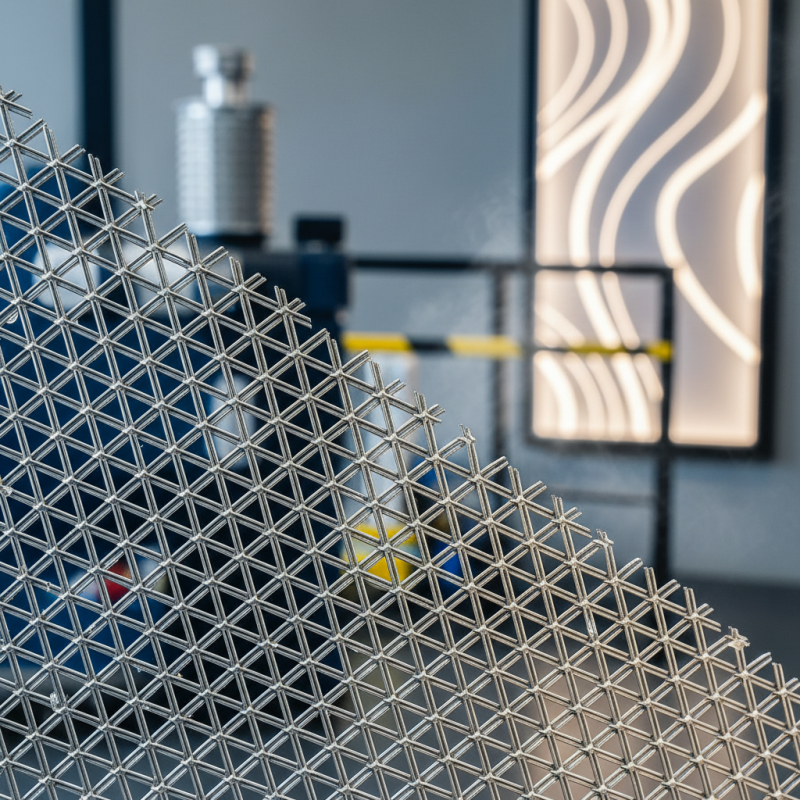

stainless steel woven wire mesh is a versatile material used in various industrial applications. Its unique properties make it a popular choice for many projects. This wire mesh is known for its strength and durability. It resists corrosion and can withstand extreme temperatures. These features ensure a long lifespan, even in harsh environments.

One of the significant benefits of stainless steel woven wire mesh is its adaptability. It can be used in filtration, safety screens, or decorative applications. Its aesthetic appeal adds value to any design. Additionally, the ease of maintenance is another reason many industries prefer it. Cleaning is simple and requires minimal effort.

Despite its many advantages, it’s essential to consider the cost. Stainless steel woven wire mesh can be more expensive than other materials. This investment must match project needs. Understanding both benefits and limitations can guide better decision-making.

Benefits of Stainless Steel Woven Wire Mesh in Industrial Applications

Stainless steel woven wire mesh has become increasingly popular in various industrial applications. Its durability and resilience make it an ideal choice for many sectors. For instance, the automotive and aerospace industries benefit greatly from its strength and resistance to corrosion. This type of mesh can withstand harsh environments, ensuring longevity and safety.

Another significant advantage is its versatility. The mesh can be used in filtration, sieving, and separation processes. It delivers precise and consistent results, critical in manufacturing. However, maintenance can be tricky. Regular cleaning and inspections are necessary to avoid potential issues. While stainless steel is resilient, it is not impervious to wear over time.

The aesthetic appeal of stainless steel woven wire mesh also stands out. It enhances product presentation in the food and beverage industries. Yet, one must consider that improper design can lead to functionality problems. Balancing aesthetics and performance requires careful planning. This material offers many benefits, but it also demands thoughtful application.

Enhanced Durability: Resistance to Corrosion and High Temperatures

Stainless steel woven wire mesh offers enhanced durability that is hard to overlook. This material excels in resisting corrosion, making it ideal for various environments. Whether in humid conditions or exposed to chemicals, it maintains its integrity. It doesn’t rust like other metals. A simple wipe can keep it looking new.

High temperatures are another area where stainless steel shines. It can withstand extreme heat without warping or degrading. In industrial applications, this property is crucial. Imagine a manufacturing plant operating with flawless mesh that doesn’t buckle under pressure. Such reliability is invaluable.

Yet, despite these strengths, one must consider the cost. Stainless steel can be more expensive than other materials. Sometimes, people choose cheaper options, only to face issues later. Reflecting on the balance between cost and quality is essential. Ultimately, investing in durable materials like stainless steel can save money in the long run.

Versatile Uses: From Filtration to Architectural Design

Stainless steel woven wire mesh is increasingly recognized for its versatility in various applications. It is widely used in filtration systems for liquids and gases. In fact, the global filtration market is projected to reach $98 billion by 2027. This growth highlights the importance of reliable materials like stainless steel that can withstand corrosive environments and high pressures.

In architectural design, stainless steel woven wire mesh adds both functionality and aesthetic appeal. It can be incorporated into facades, balustrades, and sunshades. A recent design study indicates that using stainless steel mesh can reduce energy consumption by up to 30% when used in building exteriors. This mesh not only provides shade but also enhances the building's visual impact, blurring the line between utility and beauty.

However, challenges exist in sourcing premium quality stainless steel for these applications. Not all meshes deliver the expected durability. Some manufacturers may cut corners, affecting the mesh's structural integrity. It's crucial for buyers to consider certifications that confirm the manufacturing quality. Selection matters. Choosing inferior products may result in greater long-term costs.

Cost-Effectiveness: Long-Term Savings Through Reduced Maintenance

Stainless steel woven wire mesh offers significant cost-effectiveness, especially through reduced maintenance expenses. A report by the Global Industrial Mesh Market estimated that businesses can save up to 30% on maintenance costs when switching to stainless steel from traditional materials. This material is resistant to corrosion and wear, ensuring durability over years of use.

The mesh withstands harsh environments where other materials falter. In industries like food processing and chemical manufacturing, stainless steel's longevity means less frequent replacements. Data shows that mesh components can last twice as long as plastic or carbon steel alternatives. This directly translates to lower labor and replacement expenses in the long run.

However, it’s essential to note that initial investment costs may be higher. Some businesses hesitate, fearing upfront price tags. Yet, the return on investment can be quick. After just a few years, savings from reduced maintenance often outweigh the initial costs. It is crucial for managers to analyze their long-term budget and maintenance needs before making a decision. Choosing the right material can be challenging but ultimately rewarding.

Health and Safety: Hygienic Properties for Food and Medical Industries

Stainless steel woven wire mesh is increasingly popular in health and safety applications. Its hygienic properties make it ideal for food and medical industries. Unlike other materials, stainless steel does not harbor bacteria. This characteristic is crucial for facilities handling food. Restaurants and hospitals often demand high sanitation standards.

This mesh is easy to clean. Regular washing can prevent contamination. However, it can get scratched or damaged if not handled carefully. These imperfections may become breeding grounds for germs. Thus, maintenance is important. It's vital to inspect the mesh regularly, ensuring it remains in optimal condition.

In medical environments, sterile conditions are non-negotiable. Stainless steel's resistance to corrosion means it lasts longer than many other materials. This durability translates into cost savings over time. Yet, users must remain vigilant. Even minor flaws can compromise hygiene. It's essential to prioritize quality and inspect regularly.

Top 5 Benefits of Stainless Steel Woven Wire Mesh

| Benefit | Description | Application |

|---|---|---|

| Hygienic Properties | Stainless steel is non-porous and can be easily cleaned, making it ideal for sanitary applications. | Food processing, Medical equipment |

| Corrosion Resistance | Stainless steel resists rust and chemical corrosion, ensuring longevity in harsh environments. | Industrial applications, Outdoor use |

| Durability | Stainless steel woven wire mesh is strong and withstands significant wear and tear. | Construction, Mining |

| Versatility | Can be manufactured in various configurations to fit diverse industrial needs. | Filter screens, Grilles |

| Aesthetic Appeal | Provides a sleek and modern appearance suitable for decorative applications. | Interior design, Facades |