ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreHow to Choose the Right Sachet Packaging Machine for Your Business Needs

The global sachet packaging machine market has been experiencing significant growth, driven by the increasing demand for flexible and convenient packaging solutions across various industries. According to a recent report by Grand View Research, the sachet packaging market is projected to reach USD 16.3 billion by 2025, with a CAGR of 6.2% from 2019 to 2025. As businesses strive to enhance product appeal and ensure optimal shelf life, selecting the right sachet packaging machine has become critically important. This guide aims to provide insights into key considerations for choosing a sachet packaging machine that aligns with your specific business needs, ensuring efficiency and effectiveness in your packaging operations while adapting to evolving market trends. Understanding the various features, technology options, and material compatibility of sachet packaging machines can empower businesses to make informed decisions that enhance productivity and drive consumer satisfaction.

Understanding Different Types of Sachet Packaging Machines Available in the Market

When selecting a sachet packaging machine, it is crucial to understand the various types available in the market. The primary categories include vertical form fill seal (VFFS) machines, horizontal form fill seal (HFFS) machines, and pre-made pouch machines. According to a recent report by MarketsandMarkets, the global sachet packaging market is projected to grow to $5.3 billion by 2025, with VFFS machines leading the segment due to their efficiency in high-volume production. These machines are ideal for packaging granular, powdered, and liquid products, making them versatile for industries ranging from food to pharmaceuticals.

HFFS machines, on the other hand, offer advantages for products requiring a more robust packaging solution. Typically used for non-food items, such as detergents and personal care products, these machines produce pouches that are filled from the side, allowing for more complex designs. A study by Mordor Intelligence reports that the demand for HFFS systems is surging, driven by the need for flexible packaging solutions that attract consumers.

Understanding these differences is essential for businesses to choose the right machine tailored to their specific product needs and production goals.

Key Factors to Consider When Selecting a Sachet Packaging Machine

When selecting a sachet packaging machine, it's essential to consider several key factors to ensure it meets your business needs effectively. First and foremost, the type of product to be packaged plays a crucial role in the decision-making process. Different products, whether they are liquids, powders, or granules, require specific machines designed to handle their unique characteristics. For instance, a liquid packaging machine must ensure precise dosing and sealing to prevent leaks, whereas a powder packaging machine needs to address issues like aeration and flowability.

Another critical consideration is the packaging material you intend to use. With an increasing demand for sustainable solutions, businesses are shifting towards eco-friendly options, such as paper and biodegradable plastics. Evaluating the compatibility of your chosen machine with various materials—be it plastic, paper, or aluminum—will help in streamlining operations and reducing waste. Additionally, machine automation and production speed are vital factors. Investing in a semi-automatic or fully automatic machine can significantly enhance efficiency, especially for high-volume production environments, ensuring not just output, but also consistency in packaging quality. Thus, addressing these aspects allows for a well-informed choice that aligns with your operational requirements and market trends.

Comparing Manual vs. Automatic Sachet Packaging Solutions

When deciding between manual and automatic sachet packaging solutions, understanding the specific needs of your business is paramount. Manual machines, while often more affordable, require a greater investment in labor and may limit production efficiency. These systems typically suit smaller operations or startups that may not yet have the demand for a fully automated line. They offer flexibility and ease of setup, making them ideal for businesses with fluctuating production volumes.

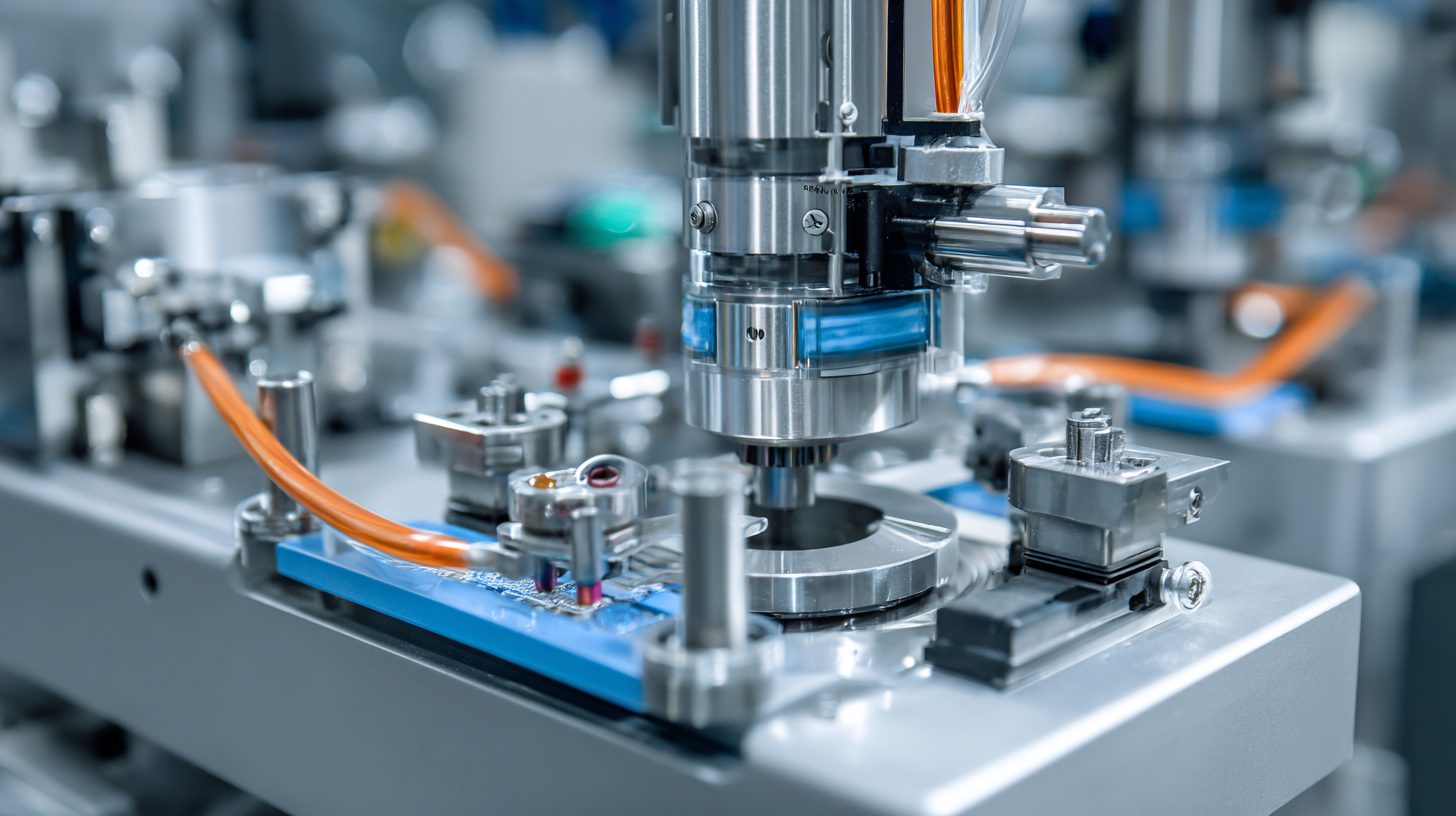

On the other hand, automatic sachet packaging solutions have evolved significantly, particularly with recent innovations in the packaging industry. For instance, the introduction of semi-automatic pouch loaders has set a new standard for efficiency and speed. These machines enhance the filling process and cater to high-volume production while still allowing for manual intervention when necessary. The versatility of such automated systems aligns well with the diverse needs of today's market, allowing businesses to scale operations without compromising on product quality or consistency. Ultimately, the choice between manual and automatic solutions should be guided by factors such as production capacity, budget, and the specific demands of your product line.

Assessing Production Capacity and Speed for Your Packaging Needs

When selecting a sachet packaging machine for your business, assessing production capacity and speed is critical. The production capacity of a machine refers to the number of sachets it can produce within a specified time frame. This metric is especially important for businesses with high demand, as insufficient capacity could lead to bottlenecks and delayed fulfillment. Evaluating your current and projected output requirements will help you avoid over- or under-investing in equipment.

Speed is another vital factor to consider. A faster machine may increase throughput, allowing your business to respond quickly to orders and market changes. However, speed should not come at the expense of quality; it is crucial to ensure that the machine maintains high sealing integrity and accuracy, regardless of how quickly it operates. Understanding your specific product's characteristics, such as viscosity and packaging material, can aid in selecting a machine that balances speed and reliability.

Determining Budget Constraints and Cost-Effectiveness in Machine Selection

When selecting a sachet packaging machine for your business, budget constraints and cost-effectiveness play a pivotal role in your decision-making process. It's essential to evaluate not only the initial cost of the machine but also the long-term expenses associated with its operation. Include factors such as energy consumption, maintenance costs, and the availability of spare parts in your assessment. This holistic approach ensures you choose a machine that fits seamlessly within your financial framework.

**Tip:** Before making a purchase, research the total cost of ownership (TCO) for potential machines. This includes initial investment, operational costs, and potential downtimes. By calculating TCO, you can make more informed comparisons between different models and manufacturers.

Additionally, consider the machine's scalability in relation to your budget. Investing in a machine that can grow with your business is often more cost-effective than frequently upgrading to meet increasing demand. Look for features that allow for easy adjustments and enhancements over time without incurring significant expenditure.

**Tip:** Consult with packaging experts or industry peers to gain insights on which machines have proven cost-effective over time. Their firsthand experiences can guide you toward choices that not only fit your budget but also deliver value.

Cost-Effectiveness of Different Sachet Packaging Machines

This chart displays the estimated budget constraints and cost-effectiveness of various sachet packaging machines based on their features and operational costs. Understanding these factors can help businesses make informed decisions when selecting a packaging solution.

Related Posts

-

The Future of Sachet Filling Machines Transforming Packaging Efficiency and Sustainability

-

Exploring the Surge in Global Demand for Sachet Packaging at the 137th Canton Fair

-

Form Fill Seal Machines in Different Manufacturing Sectors A Comparative Analysis

-

Exploring Innovative Examples of the Best Case Packing Techniques for Enhanced Efficiency

-

Top 10 Case Packing Equipment Manufacturers from China at the 137th Canton Fair

-

Future-Proofing Your Supply Chain: Key Innovations in Pouch Packaging by 2025