ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreHow to Choose the Best Pouch Filler for Your Packaging Needs?

Choosing the right Pouch Filler for your packaging needs can be daunting. As John Smith, a leading expert in packaging technology, stated, "The right equipment can make or break your production line." Selecting a Pouch Filler is not just about capacity; it’s about efficiency and quality.

Why does it matter? A poorly matched Pouch Filler can lead to wasted time and resources. Take, for example, coffee packaging. Different products need specific fillers. The wrong choice can spoil freshness and compromise quality.

Additionally, consider the flexibility of designs. Some Pouch Fillers handle various sizes, while others are limited. This could mean significant adjustments in production if the wrong decision is made. It’s essential to reflect on your specific requirements and future growth. Missteps can lead to costly upgrades or replacements. Therefore, understanding your needs and the options available is crucial in this crucial decision-making process.

Understanding Different Types of Pouch Fillers Available in the Market

When choosing a pouch filler, it’s essential to understand the types available. Each type serves different needs.

For instance, gravity fillers use weight to dispense product. They work well for free-flowing items, like granules or powders.

However, they may struggle with thick substances.

Auger fillers are another option. They are designed for thick, viscous materials, such as pastes and creams.

But, the setup can be complicated. It may require more maintenance than other types.

Additionally, the speed of filling might not be ideal for all production lines.

Vacuum fillers are great for liquids. They can handle thin and thick liquids, ensuring accuracy.

However, their initial cost can be high. Some operations might not need such precision.

This could lead to underperformance.

Understanding these options helps tailor your choice to your specific needs.

Assessing Your Packaging Requirements and Product Characteristics

When choosing the right pouch filler, understanding your packaging requirements is crucial. It involves assessing the nature of your product. For instance, powders, liquids, and granules each have unique handling characteristics. According to a recent industry report, around 40% of companies face challenges related to product compatibility with their chosen fillers. Proper assessments can prevent operational disruptions.

Consider the size and shape of your product. Products with irregular shapes may require specific pouch designs. Data shows that nearly 30% of businesses review their pouch dimensions only after facing filling inefficiencies. This oversight can lead to waste and increased costs. Additionally, the filling speed must align with your production goals; a slower machine may affect your overall output.

Moreover, think about the materials of your pouches. Certain substances react differently to varying products, impacting shelf life and quality. Research indicates that over 50% of packaging failures arise from material mismatches. This aspect often demands reflection and reevaluation of previous choices. Making informed decisions can enhance both the efficiency and quality of your packaging process.

Analysis of Packaging Requirements for Pouch Fillers

This chart illustrates the required filling speeds for various product types in pouch filling operations. Understanding these requirements is essential for selecting the appropriate pouch filler that meets the packaging needs effectively.

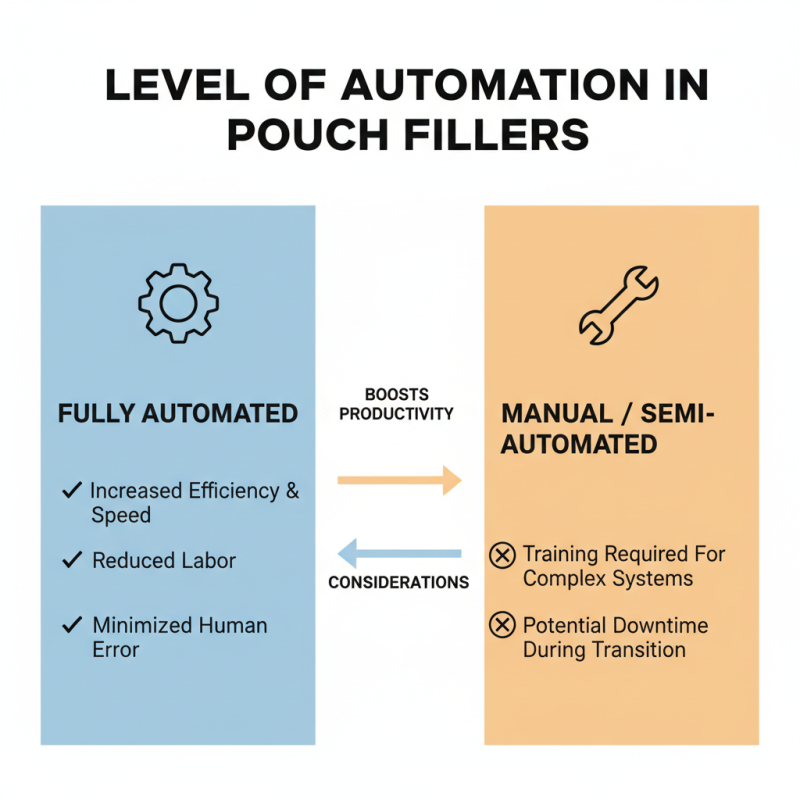

Evaluating the Automation Level of Pouch Fillers

When evaluating pouch fillers, the level of automation is crucial. Fully automated machines can boost efficiency and speed. They decrease the need for manual labor and reduce human error. However, some businesses might find training required for operating complex systems. This can lead to downtime during the transition period.

Mid-level automated pouch fillers provide a balance. They often include semi-automated aspects, allowing for quick adjustments. Users can operate them with less training, which is helpful for smaller operations. Still, mismatches in packaging sizes may occur. Frequent recalibrations can be a hassle.

In contrast, manual pouch filling requires hands-on work, which has its benefits. It allows for changes on the fly. However, it often leads to inconsistent fill levels. This might add to production costs over time. Evaluating your specific packaging needs is vital. The best choice depends on your production volume and flexibility requirements.

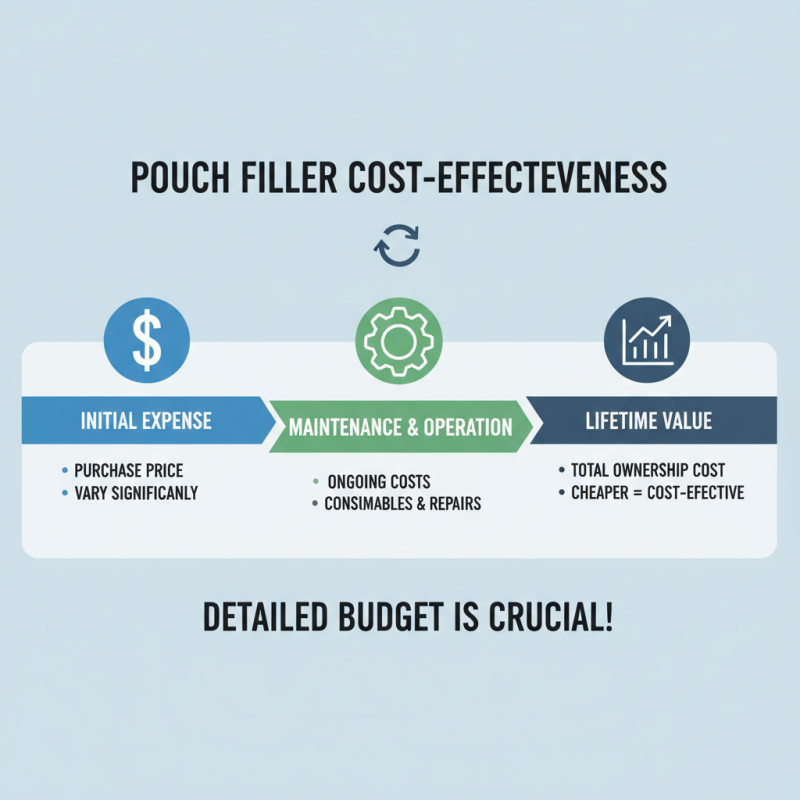

Analyzing Cost-Effectiveness and Budget Considerations

When evaluating pouch fillers, cost-effectiveness is crucial. The initial expense can vary significantly. Make a detailed budget to understand potential costs. Consider not just the purchase price but also maintenance and operation. Cheaper machines may incur higher expenses over time. Maintenance costs can add up, impacting your budget.

Next, think about the production volume. If you plan to scale up, invest in a machine that meets future demands. Smaller machines might suffice initially, but they may lead to bottlenecks. Take into account the materials being used as well. Some machines work better with specific pouch types. This can affect both efficiency and material costs.

Consider training and integration. Implementing new machinery often requires time and resources. If staff need extensive training, factor this into your budget. Furthermore, revisit your selected equipment after a trial period. Is it living up to expectations? Are there areas for improvement? Reflecting on this can lead to better choices in the future.

Researching Manufacturer Support and Maintenance Services

When choosing a pouch filler, consider the manufacturer’s support and maintenance services. This aspect often gets overlooked, yet it is crucial for long-term success. If a machine breaks down, timely support can minimize downtime. Check if the manufacturer offers comprehensive service packages. Do they provide training for your staff? This can help ensure that your team operates the machine efficiently.

Tips: Investigate the response time for support requests. A quick turnaround is essential for smooth operations. Additionally, ask about spare parts availability. A reliable supplier will have essential components readily on hand.

Don’t underestimate the importance of maintenance. Regular upkeep can extend the life of your pouch filler. Some machines may require more frequent servicing than others. Research if the manufacturer offers easy-to-follow maintenance guidelines. Having a user-friendly manual can save you from costly mistakes. It's worth discussing these details before making a purchase.

How to Choose the Best Pouch Filler for Your Packaging Needs?

| Feature | Description | Importance | Example Consideration |

|---|---|---|---|

| Filling Accuracy | The precision of volume dispensed | High | Necessary for product quality control |

| Speed of Operation | Speed of cycle completion (filling and sealing) | Medium | Direct impact on productivity rates |

| Ease of Use | User-friendliness of the control interface | High | Reduces training time for staff |

| Maintenance Support | Availability of technical support and replacement parts | High | Minimizes downtime for repair |

| Versatility | Capability to handle different pouch sizes and materials | Medium | Future-proofing against product line changes |

| Cost of Ownership | Total cost including purchase, maintenance, and operation | High | Budget impact and ROI analysis |

Related Posts

-

The Future of Packaging Solutions: Revolutionizing Production with the Best Pouch Filler

-

Essential Insights for Sourcing Pouch Packaging Machines Globally

-

Top Trends in Pouch Packaging Machine Innovations Transforming Global Supply Chains

-

5 Essential Insights for Choosing the Right Pouch Packaging Machine

-

How to Choose the Right Sachet Packaging Machine for Your Business Needs

-

Ultimate Guide to Choosing the Best Packaging Equipment: Insights and Data for Optimal Efficiency