ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreUnderstanding the Functionality of Form Fill And Seal Machines

In the dynamic landscape of packaging technology, the Form Fill And Seal Machine plays a pivotal role in enhancing operational efficiency and product integrity. According to a recent market report by Grand View Research, the global packaging machinery market is projected to reach USD 50.89 billion by 2025, with Form Fill And Seal Machines being a significant contributor to this growth due to their ability to streamline processes and reduce labor costs. These machines not only automate the packaging process but also ensure consistency and quality across various industries, from food and beverages to pharmaceuticals. As manufacturers increasingly prioritize sustainability and cost-effectiveness, understanding the functionality and advantages of Form Fill And Seal Machines becomes essential for businesses aiming to remain competitive and meet evolving consumer demands.

Overview of Form Fill and Seal Machines: Key Components and Their Roles

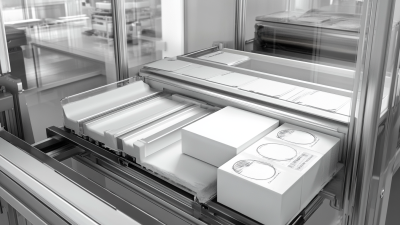

Form Fill and Seal (FFS) machines play a crucial role in the packaging industry, seamlessly integrating the processes of forming bags, filling them with product, and sealing them—all in one continuous operation. The key components of these machines include the forming station, filling station, and sealing station. According to a report by MarketsandMarkets, the global FFS packaging market is projected to reach USD 24.8 billion by 2025, driven largely by the demand for efficient and cost-effective packaging solutions.

The forming station utilizes rolls of thermoplastic film to create bags of varying sizes and shapes, tailored specifically to the product being packaged. Following this, the filling station efficiently dispenses the desired product into the formed bags, with advanced machines increasingly using automation for improved speed and precision. Finally, the sealing station ensures that the bags are securely closed, employing techniques such as heat sealing or ultrasonic sealing. In fact, a study published by Allied Market Research indicates that the heat sealing segment alone is expected to dominate the FFS machinery market, highlighting the importance of proper sealing methods in maintaining product integrity and extending shelf life.

Understanding the Functionality of Form Fill And Seal Machines - Overview of Form Fill and Seal Machines: Key Components and Their Roles

| Component | Function | Material Type | Common Applications |

|---|---|---|---|

| Film Feed | Supplies packaging material from reels | Flexible plastic films, laminated materials | Food products, pharmaceuticals |

| Filler | Dispenses the product into the formed package | Varies by product (liquid, powder, solid) | Beverages, granules, snacks |

| Sealing System | Creates airtight seals on the packages | Heat sealable materials | Ready-to-eat meals, frozen foods |

| Cutting Unit | Cuts the film to create individual packages | Depends on film type | Snacks, condiments, detergent |

| Control System | Monitors and adjusts machine operations | Electronic components and software | All types of packaging |

How Form Fill and Seal Machines Improve Packaging Efficiency and Speed

Form Fill and Seal (FFS) machines are revolutionizing the packaging industry by significantly enhancing efficiency and speed. These innovative machines automate the entire process of packaging from forming the package to filling it with the product and sealing it, all in one continuous operation. This streamlined approach not only reduces labor costs but also minimizes the chances of human error, ensuring a higher quality end product. Businesses can benefit from quick setup times and easy adjustments, allowing for flexibility in packaging different products without extensive downtime.

To maximize the efficiency of FFS machines, it’s essential to maintain optimal machine settings. Regularly calibrating the filling volume and adjusting the sealing temperature can greatly impact the speed of production. Additionally, using high-quality materials is crucial; they can withstand the heat and seal properly, reducing the likelihood of product spoilage.

Furthermore, integrating these machines with inventory and production management systems can create a more seamless workflow. Real-time monitoring of production metrics helps companies identify bottlenecks and areas for improvement, thus enhancing overall productivity. Implementing these strategies will not only lead to quicker packaging solutions but also contribute to higher customer satisfaction through reliable and efficient service.

Different Types of Form Fill and Seal Machines and Their Applications

Form fill and seal machines (FFS) are critical in the packaging industry, offering efficiency and versatility across various sectors. There are several types of FFS machines, each tailored for specific applications. For instance, vertical form fill and seal machines are ideal for packaging granular products like rice, sugar, and pet food. They operate by forming a tube from a flat roll of film, filling it with the desired product, and sealing it — all in a continuous cycle. Their compact design and speed make them a popular choice for high-volume packaging operations.

Form fill and seal machines (FFS) are critical in the packaging industry, offering efficiency and versatility across various sectors. There are several types of FFS machines, each tailored for specific applications. For instance, vertical form fill and seal machines are ideal for packaging granular products like rice, sugar, and pet food. They operate by forming a tube from a flat roll of film, filling it with the desired product, and sealing it — all in a continuous cycle. Their compact design and speed make them a popular choice for high-volume packaging operations.

On the other hand, horizontal form fill and seal machines are perfect for packaging products that require greater flexibility in design and size, such as bakery items or frozen foods. This type of machine allows for easier handling of irregularly shaped products, providing a reliable sealing mechanism that preserves freshness. In addition to these, semi-automatic and fully automatic FFS machines cater to different levels of production needs, enabling manufacturers to choose the best fit for their operational scale and product types. Understanding these various machines and their specific applications is essential for businesses aiming to enhance productivity and ensure product quality.

Common Challenges in Using Form Fill and Seal Machines and Solutions

Form Fill and Seal (FFS) machines are essential in modern packaging operations, providing efficiency and speed. However, users often encounter challenges that can affect productivity and product quality. For instance, a report from PMMI highlights that nearly 30% of packaging downtime is caused by machine errors, which can stem from inadequate maintenance or improper operator training. Addressing these issues is critical for optimizing the performance of FFS machines.

One common challenge is the proper sealing of packages, which can lead to product spoilage or leakage. Ensuring correct temperature and pressure settings is vital. According to a study by the Packaging Machinery Manufacturers Institute, inconsistent sealing parameters can reduce seal strength by up to 25%. Regularly calibrating machines and conducting routine maintenance can mitigate these risks, enhancing overall packaging integrity.

**Tips:** Implement a scheduled training program for operators to familiarize them with the technology and troubleshooting techniques. Additionally, invest in predictive maintenance technologies to catch potential issues before they cause significant downtime. Regularly reviewing machine performance data can help identify patterns and preemptively address challenges in the packaging process.

Future Trends in Form Fill and Seal Technology and Their Implications

In the evolving landscape of packaging technology, form fill and seal (FFS) machines are at the forefront of innovation. As industries embrace automation and sustainability, the future of FFS technology is poised to incorporate advanced features that not only enhance efficiency but also minimize environmental impact. One key trend is the integration of smart technology, allowing machines to communicate in real-time, gather operational data, and enable predictive maintenance. This digital transformation can significantly reduce downtime and improve production quality, making FFS machines more reliable and cost-effective.

Another promising trend is the shift towards biodegradable and compostable packaging materials. With increasing consumer demand for sustainable solutions, manufacturers are exploring new materials that can be processed by FFS machines without compromising performance. This evolution not only meets regulatory pressures but also caters to eco-conscious consumers looking for greener options. As FFS technology continues to advance, the implications for manufacturers and consumers alike will be significant, paving the way for a more sustainable and efficient future in packaging.

Related Posts

-

The Future of Packaging Solutions: Revolutionizing Production with the Best Pouch Filler

-

How to Choose the Best Packaging Options for Global Supply Chains: Insights and Data

-

Future-Proofing Your Supply Chain: Key Innovations in Pouch Packaging by 2025

-

Innovative Approaches to Packaging Machines in 2025 Trends and Eco-Friendly Alternatives

-

Discover Top-Quality Packaging Systems from China's Leading Manufacturing Experts

-

Understanding the Benefits of Best Form Fill Seal Technology