ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreThe Future of Packaging Solutions: Revolutionizing Production with the Best Pouch Filler

In an era where efficiency and sustainability are paramount, the selection of packaging solutions has become crucial for businesses looking to thrive. Among the myriad of options available, the Pouch Filler stands out as a game-changer in the packaging industry. This innovative technology streamlines production processes while ensuring that products are neatly packaged for distribution. However, not all pouch fillers are created equal, and choosing a quality manufacturer is essential to guarantee optimal performance and reliability. In this blog, we will explore the key factors to consider when selecting a top-notch pouch filler manufacturer, from understanding your specific packaging needs to evaluating the manufacturer’s technology and service offerings. By making informed decisions, businesses can revolutionize their production and position themselves competitively in the market, paving the way for a sustainable and efficient future.

Innovative Trends in Packaging: Embracing Advanced Pouch Filling Technologies

In today's fast-paced market, the packaging industry is undergoing a significant transformation, with advanced pouch filling technologies leading the charge. As manufacturers aim for efficiency and sustainability, innovative trends such as eco-friendly materials and smart packaging solutions are gaining traction. By integrating automated pouch fillers, companies are not only enhancing production speed but also minimizing waste, which contributes to their overall sustainability goals. This shift towards greater automation allows for a more streamlined process, minimizing human error and increasing overall product integrity.

Another noteworthy trend is the rise of customizable packaging solutions. Modern consumers are seeking personalized experiences, and pouch filling technologies are adapting to meet this demand. With the ability to create various sizes and styles of pouches, brands can cater to specific market needs and preferences. Additionally, advanced filling equipment can handle a wider range of product types, from liquids to solids, allowing for greater versatility in product offerings. By embracing these innovative trends, businesses can stay ahead of the curve and enhance their competitive edge in the ever-evolving packaging landscape.

The Future of Packaging Solutions: Revolutionizing Production with the Best Pouch Filler

| Technology Type | Efficiency (%) | Speed (Pouches/hour) | Automation Level | Sustainability Features |

|---|---|---|---|---|

| Horizontal Pouch Fillers | 95 | 120 | High | Biodegradable materials |

| Vertical Pouch Fillers | 90 | 150 | Medium | Recyclable packaging |

| Automatic Pouch Fillers | 98 | 200 | Very High | Energy-efficient designs |

| Semi-Automatic Pouch Fillers | 85 | 80 | Low | Use of recycled materials |

The Role of Automation in Enhancing Production Efficiency

The rapidly evolving landscape of packaging solutions is increasingly being shaped by automation, dramatically enhancing production efficiency in various industries.

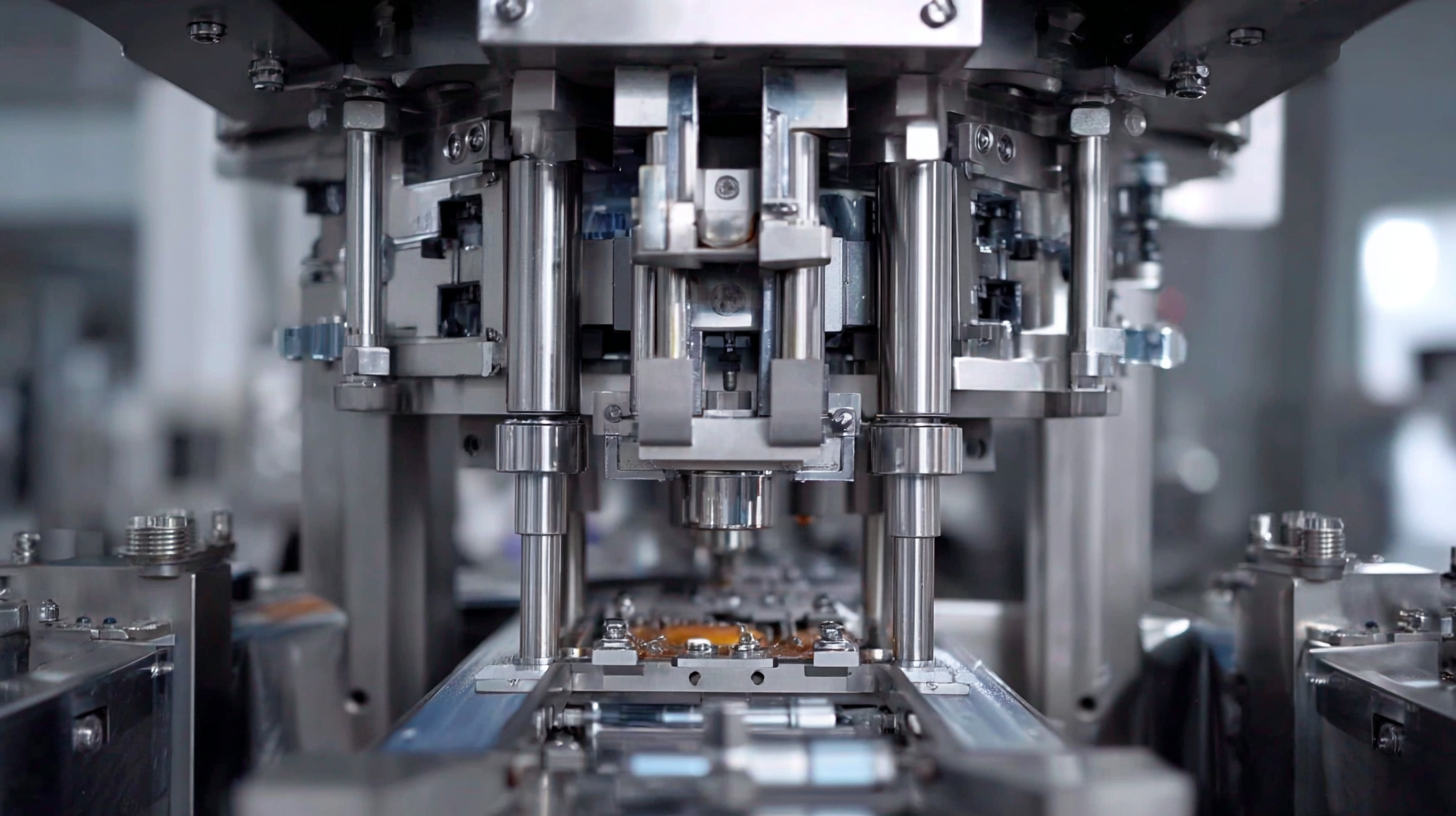

Automated pouch fillers play a pivotal role in this transformation, offering businesses the ability to streamline their operations. By reducing manual labor and minimizing human error, automated systems ensure that products are filled with precision and consistency, which not only saves time but also significantly lowers production costs.

Automated pouch fillers play a pivotal role in this transformation, offering businesses the ability to streamline their operations. By reducing manual labor and minimizing human error, automated systems ensure that products are filled with precision and consistency, which not only saves time but also significantly lowers production costs.

Moreover, the integration of smart technology further amplifies these benefits. With real-time data analytics and machine learning capabilities, modern pouch fillers can adapt to changing production needs, optimizing workflows and reducing downtime. This level of flexibility allows manufacturers to respond more effectively to market demands, all while maintaining high-quality standards.

As companies continue to embrace automation, the future of packaging solutions is set to become even more efficient, paving the way for a seamless and sustainable production process that meets the criteria of the modern market.

Sustainable Practices in Pouch Filling: Meeting Environmental Challenges

Sustainable practices in pouch filling are increasingly important as industries seek to meet environmental challenges while maintaining efficient production. Packaging solutions are evolving, and the adoption of eco-friendly materials and processes is essential for reducing waste and promoting sustainability. For instance, the case of the Aral Sea highlights the consequences of unsustainable resource usage, emphasizing the need for a shift towards methods that safeguard both natural ecosystems and local communities.

To implement sustainable pouch-filling practices, consider using biodegradable materials and optimizing the filling process to minimize excess waste. Additionally, companies should invest in certification programs that promote responsible sourcing and manufacturing. Such initiatives not only enhance brand reputation but also contribute to broader environmental goals, as seen in coffee certification efforts worldwide aimed at sustainable agriculture and improving livelihoods.

Another tip is to adopt Lean Six Sigma principles in pouch filling operations. This data-driven approach can help identify inefficiencies and reduce environmental impact by streamlining processes. By creating a culture of sustainability within organizations, employees are more likely to engage in pro-environmental behaviors, further supporting the shift towards sustainable practices in production.

Quality Control Measures in Pouch Filling for Optimal Product Integrity

In the rapidly evolving landscape of packaging solutions, maintaining product integrity through quality control measures is paramount. Pouch filling, a popular choice for many manufacturers, requires rigorous oversight to ensure that products are packaged correctly and meet customer expectations. One of the most effective ways to enhance quality control in pouch filling is to implement a comprehensive monitoring system. This could include real-time tracking of fill weights and sealing integrity, as well as regular audits of the machinery to prevent discrepancies.

Tips for ensuring optimal product integrity in pouch filling include conducting regular training sessions for staff on best practices and maintaining an efficient maintenance schedule for all equipment. Additionally, utilizing automated systems that offer feedback mechanisms can significantly reduce human error during the filling process. By adopting these practices, manufacturers can minimize waste and ensure that every pouch is filled to the correct specifications.

Furthermore, investing in high-quality materials for pouches can also impact the overall quality. Transparent pouches allow for visual inspections, while tamper-evident features increase consumer confidence. Smart packaging technologies that incorporate QR codes or sensors for freshness can add another layer of quality assurance that resonates with today’s quality-conscious consumers. By focusing on these quality control measures, manufacturers can continue to innovate and lead in the competitive world of pouch filling.

China's Leadership in Global Packaging Solutions: Driving Future Innovations

China has emerged as a pivotal player in the global packaging solutions market, showcasing its innovative prowess and commitment to quality. With a robust manufacturing framework and advanced technology, Chinese companies are leading the charge in developing more efficient and sustainable packaging options. This leadership is not just confined to traditional packaging but extends to cutting-edge solutions such as flexible pouches, which are becoming increasingly popular due to their convenience and reduced environmental impact.

The drive for innovation in packaging within China is fueled by a combination of research and development investments and collaborations with international partners. These efforts have resulted in significant advancements, including enhanced pouch filling machinery that optimizes production efficiency while maintaining product integrity. As the demand for sustainable packaging solutions continues to grow globally, China's ability to adapt and innovate positions it as a crucial contributor to the evolution of packaging practices worldwide, setting the stage for a future that embraces sustainability and technology.

The Future of Packaging Solutions

This chart illustrates the market share of various packaging types, highlighting the importance of flexible packaging in modern production processes. As China leads in global packaging innovations, these data points reflect current trends and anticipations for future developments in the industry.