ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreUltimate Guide to Form Fill Seal Machine Applications and Benefits

In the rapidly evolving landscape of packaging technology, the Form Fill Seal Machine has emerged as a cornerstone of efficiency and innovation across various industries. As per recent industry reports, the global packaging machinery market is projected to reach $60 billion by 2028, significantly propelled by advancements in automated solutions. Form Fill Seal Machines, known for their ability to simultaneously form, fill, and seal pouches and containers, play a crucial role in this growth trajectory, enhancing production speed and reducing labor costs.

The mechanization of packaging processes through Form Fill Seal Machines not only streamlines operations but also addresses the increasing demand for versatility and quality in packaging solutions. Recent statistics indicate that the demand for flexible packaging, in which Form Fill Seal Machines are particularly effective, is expected to grow at a CAGR of over 4% during the next five years. This growth underscores the necessity for manufacturers to adopt automated technologies that ensure product integrity while accommodating a variety of product shapes and sizes. As industries seek to optimize productivity while maintaining stringent safety and hygiene standards, the relevance and benefits of Form Fill Seal Machines remain paramount.

Overview of Form Fill Seal Machines and Their Functionality

Form Fill Seal (FFS) machines are sophisticated systems designed for packaging a wide variety of products, ranging from liquids and powders to solids. These machines automate the processes of forming packaging, filling it with a product, and sealing it, thus significantly enhancing efficiency and productivity. According to a report by MarketsandMarkets, the global FFS machine market is projected to reach USD 23.6 billion by 2025, reflecting the increasing demand for automation in packaging processes. FFS technology not only reduces labor costs but also minimizes material wastage, making it an environmentally friendly option for manufacturers.

In terms of functionality, FFS machines utilize a series of procedures to ensure that products are adequately packaged. The process begins with the roll of packaging film, which is shaped into the required form—usually a pouch or bag. This is followed by the filling stage, where the product is introduced into the formed package, and finally, the sealing process, which ensures that the product remains fresh and protected from external contaminants. Notably, FFS machines can be customized to accommodate heat seal, cold seal, or vacuum seal techniques, catering to various product types and retention needs.

Tips: When selecting an FFS machine, consider the specific requirements of your product, such as viscosity or perishability, as this will impact the choice of sealing technology. Furthermore, regular maintenance and calibration of the FFS machine can greatly extend its operational life and ensure consistent package quality, ultimately driving customer satisfaction and loyalty.

Key Applications of Form Fill Seal Machines in Various Industries

Form fill seal machines have become essential in various industries due to their efficiency and versatility in packaging solutions. One of the most notable applications is in the food industry, where these machines are utilized to package everything from snacks to ready-to-eat meals. The ability to maintain hygiene and extend shelf life through vacuum and modified atmosphere packaging makes form fill seal machines particularly valuable for food manufacturers. They ensure that products are sealed quickly and securely, reducing waste and minimizing the risk of contamination.

In addition to food, form fill seal technology finds extensive use in the pharmaceutical and cosmetics sectors. These machines facilitate the precise packaging of tablets, ointments, and liquid products, ensuring compliance with stringent safety and quality standards. The automation capabilities of form fill seal machines allow for high-speed production lines, which are crucial for meeting the demand for pharmaceutical products while maintaining product integrity. Moreover, in cosmetics, they assist in delivering a wide array of products, from creams to serums, in an efficient and aesthetically pleasing manner, enhancing user experience while ensuring freshness.

Advantages of Using Form Fill Seal Machines for Packaging Efficiency

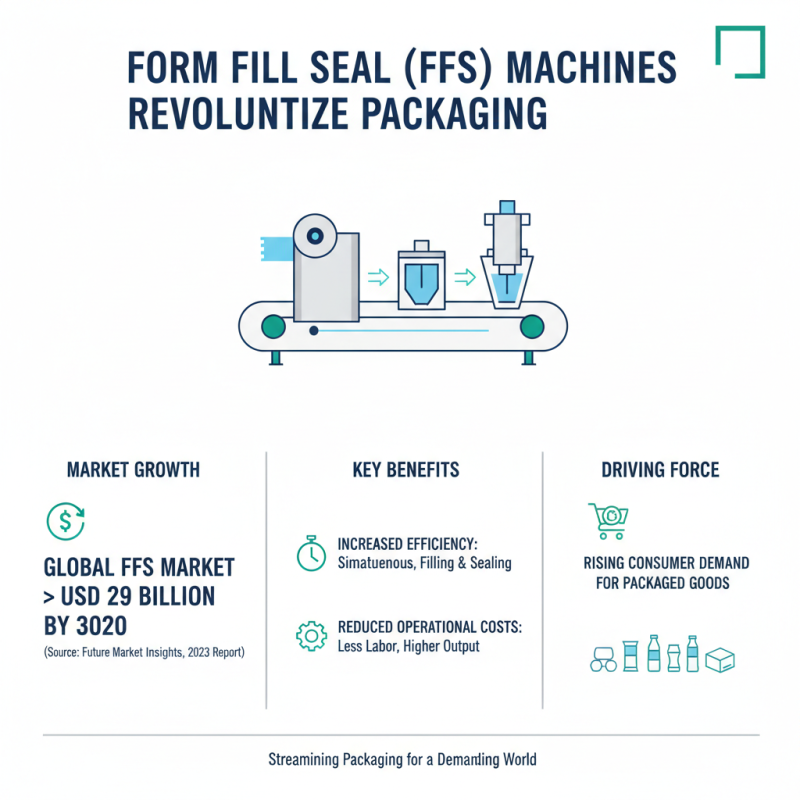

Form Fill Seal (FFS) machines have revolutionized the packaging industry by offering increased efficiency and versatility. According to a 2023 market analysis report by Future Market Insights, the global FFS market is projected to exceed USD 29 billion by 2030, primarily driven by rising consumer demand for packaged goods. These machines streamline the packaging process by simultaneously forming, filling, and sealing pouches or containers, which reduces labor costs and minimizes production time. This efficiency leads to higher output and lower operational costs for manufacturers.

One of the key advantages of FFS machines is their flexibility to handle a variety of materials and product types, making them suitable for diverse industries ranging from food and beverage to pharmaceuticals and cosmetics. A report from Technavio noted that 43% of companies in the food sector are increasingly adopting FFS technology to improve packaging consistency and reduce waste. Additionally, the automation capabilities of FFS machines contribute to enhanced hygiene standards, which are critical in sectors requiring stringent quality control, such as healthcare and food safety. The integration of advanced technologies, such as sensors and AI, has further optimized these machines, allowing for real-time monitoring and adjustments during the production process, thereby increasing overall productivity.

Comparative Analysis: Form Fill Seal vs. Other Packaging Methods

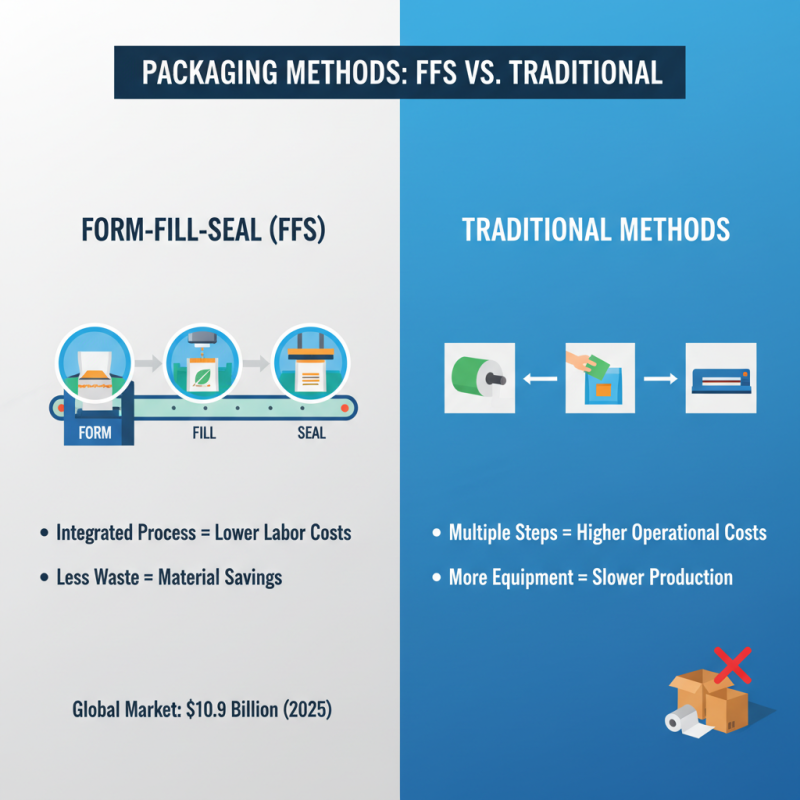

The comparative analysis of form fill seal (FFS) machines against other packaging methods highlights several advantages that have cemented FFS as a preferred choice across various industries. According to a report by MarketsandMarkets, the global form fill seal equipment market is projected to reach $10.9 billion by 2025, driven by the need for efficient and cost-effective packaging solutions. FFS machines streamline the packaging process by integrating forming, filling, and sealing into one continuous operation, resulting in reduced labor costs and minimized material waste. In contrast, traditional packaging methods often involve multiple steps and equipment, leading to higher operational costs and lengthy production times.

Moreover, a study by the Packaging Machinery Manufacturers Institute (PMMI) indicates that FFS systems can achieve packaging speeds ranging from 30 to 300 units per minute, significantly outperforming manual or semi-automated processes. This enhanced efficiency not only boosts productivity but also allows manufacturers to meet the increasing demands for quicker turnaround times in a fast-paced market environment. Additionally, FFS machines offer versatility in packaging a wide variety of products, including solids, liquids, and powders, making them a powerful solution compared to static methods like bottling or jar filling, which often require specialized machinery for each product type. As businesses prioritize efficiency and adaptability, the preference for form fill seal technology continues to rise, further impacting the packaging landscape.

Future Trends in Form Fill Seal Technology and Innovations

The future of Form Fill Seal (FFS) technology is poised for significant advancements driven by automation and smart technology integration. As manufacturers seek enhanced efficiency and precision, the incorporation of artificial intelligence (AI) and machine learning algorithms into FFS machines is expected to streamline the packing process. These innovations can enable real-time monitoring of production lines, predictive maintenance, and optimization of filling processes based on data analytics, significantly reducing downtime and waste.

Additionally, sustainability will become a central focus within the FFS realm. With growing awareness around environmental impacts, the industry is likely to see an increase in the use of biodegradable and recyclable materials. Innovations in packaging films that retain product freshness while minimizing environmental footprints will not only cater to consumer preferences but also align with global sustainability goals. Enhanced packaging solutions, such as adjustable-volume fillers and multi-layer films, will further contribute to an efficient and eco-friendly paradigm in the packaging industry, paving the way for more responsible manufacturing practices in the future.

Trends in Form Fill Seal Machine Applications

This chart illustrates the growing applications of Form Fill Seal machines across various industries from 2018 to 2023, showcasing the adoption rate and trends in packaging technology.

Related Posts

-

Innovative Form Fill Seal Examples Transforming Packaging Solutions

-

Exploring Diverse Packaging Solutions: How to Choose the Right Fit for Your Global Procurement Needs

-

Future of Packing Equipment: 2025 Innovations and How to Optimize Your Supply Chain

-

Top 10 Case Packing Equipment Manufacturers from China at the 137th Canton Fair

-

Ultimate Guide to Choosing the Best Packaging Equipment: Insights and Data for Optimal Efficiency

-

Innovative Examples of Best Packing Equipment for Global Buyers