ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreRevolutionizing Efficiency: How Innovative Packaging Equipment Enhances Supply Chain Performance

The packaging industry plays a crucial role in the efficiency of supply chains, fundamentally enhancing performance through the integration of innovative packaging equipment. According to a report by Smithers Pira, the global packaging machinery market is projected to reach $55 billion by 2028, with a CAGR of 3.5%. This surge underscores the significance of advanced packaging solutions in optimizing not only operational processes but also reducing costs and minimizing waste in supply chains.

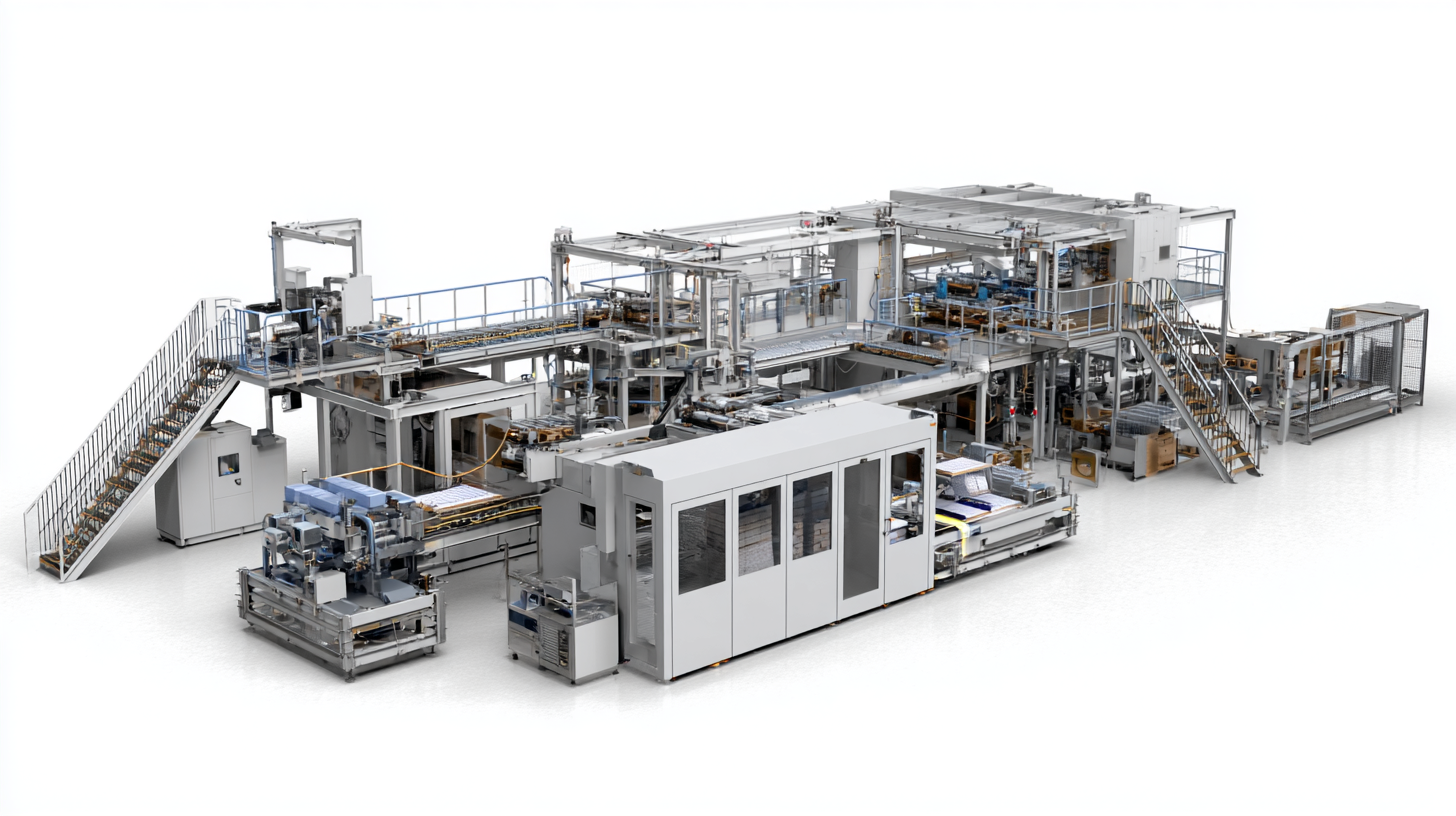

As companies grapple with increasing consumer demands and the complexities of logistics, innovative packaging equipment streamlines production, facilitates automation, and improves accuracy in supply distribution. By leveraging cutting-edge technologies such as smart packaging and robotics, businesses can significantly enhance their supply chain resilience and responsiveness, ultimately leading to improved customer satisfaction and competitive advantage in the market.

As companies grapple with increasing consumer demands and the complexities of logistics, innovative packaging equipment streamlines production, facilitates automation, and improves accuracy in supply distribution. By leveraging cutting-edge technologies such as smart packaging and robotics, businesses can significantly enhance their supply chain resilience and responsiveness, ultimately leading to improved customer satisfaction and competitive advantage in the market.

Identifying Key Innovations in Packaging Equipment for Supply Chain Optimization

Innovative packaging equipment plays a crucial role in enhancing supply chain performance, and recent market trends reflect significant growth potential.

The global reusable transport packaging (RTP) market is expected to reach a value of $25.25 billion by 2025, with a compound annual growth rate (CAGR) of 4.35%, projecting a total value of $35 billion by 2033. This growth underscores the increasing demand for sustainable packaging solutions that not only reduce waste but also improve logistics efficiency.

Additionally, the smart packaging market is set for substantial expansion, with an expected market size of $26.06 billion in 2025, rising to $40.2 billion by 2032, reflecting a CAGR of 6.32% during the forecast period. Smart packaging technologies enhance supply chain optimization by enabling better inventory management, real-time tracking, and improved product safety. As industries increasingly seek to streamline operations and reduce costs, the adoption of innovative packaging equipment becomes pivotal in driving supply chain success.

Integrating Smart Technology in Packaging to Improve Inventory Management

The integration of smart technology in packaging is transforming inventory management, enabling businesses to enhance their supply chain performance significantly. With advancements in artificial intelligence, companies can now analyze historical and real-time data more effectively, leading to more accurate demand forecasting. This ability to predict demand not only optimizes inventory levels but also minimizes excess stock, ultimately driving cost savings and operational efficiency.

Moreover, the rise of intelligent packaging solutions opens up new avenues for businesses. As the smart packaging market is projected to grow substantially, companies are investing in technologies that include IoT connectivity and robotics. This integration allows for improved tracking of goods and better management of resources throughout the supply chain. By infusing packaging with smart technologies, enterprises can achieve heightened visibility in their operations, leading to a more responsive and agile supply chain.

Streamlining Operations: Reducing Waste through Advanced Packaging Solutions

Innovative packaging solutions are playing a crucial role in streamlining operations and reducing waste within the supply chain. As businesses increasingly adopt advanced technologies, such as artificial intelligence, machine learning, and predictive analytics, the ability to enhance operational efficiency has never been more significant. These technologies allow for smarter decision-making processes, automate repetitive tasks, and facilitate real-time tracking of products, leading to a more streamlined flow of goods.

One striking example of this evolution is the collaboration between industry leaders to implement radio-frequency identification (RFID) labels. This development not only helps in tracking meat packaging but also significantly reduces food waste by ensuring better inventory management. As companies strive for sustainability, the integration of these advanced packaging solutions becomes vital. They are not only pivotal in cutting operational costs but also play a role in fostering environmentally friendly practices, demonstrating that efficiency and sustainability can go hand in hand in modern supply chains.

Revolutionizing Efficiency: How Innovative Packaging Equipment Enhances Supply Chain Performance

| Equipment Type | Efficiency Improvement (%) | Waste Reduction (% of Material) | Cost Savings ($) | Implementation Time (Months) |

|---|---|---|---|---|

| Automated Filling Machines | 20% | 15% | 50000 | 6 |

| Shrink Wrapping Systems | 25% | 10% | 30000 | 4 |

| Robotic Palletizers | 30% | 5% | 80000 | 12 |

| Case Sealers | 15% | 8% | 20000 | 3 |

Enhancing Product Protection: The Role of Innovative Packaging in Distribution

Innovative packaging plays a critical role in enhancing product protection throughout the distribution process. According to a report by Smithers Pira, the global packaging market is forecasted to reach $500 billion by 2024, driven by the increasing demand for materials that can withstand the rigors of transportation while ensuring product safety. Effective packaging minimizes damage during transit, which is crucial as the report highlights that up to 10% of products can be damaged before they reach the consumer.

Advanced packaging solutions, such as vacuum sealing and temperature-controlled packaging, are at the forefront of this revolution. These technologies not only preserve product integrity but also extend shelf life, which is particularly important in sectors such as food and pharmaceuticals where freshness is paramount. Moreover, research from the Warehousing Education and Research Council shows that improving packaging design can reduce shipping costs by up to 30%, further enhancing overall supply chain performance. By investing in innovative packaging, companies can achieve significant cost savings while simultaneously safeguarding their products.

Measuring Impact: Analyzing Efficiency Gains from Modern Packaging Practices

Innovative packaging equipment is transforming supply chain dynamics, allowing companies to achieve unprecedented efficiency gains. By utilizing modern packaging practices, businesses can streamline their operations, reduce waste, and respond more rapidly to market demands. Advanced technologies, such as automated packaging lines and smart sensors, enable precise measurement of packaging processes, leading to improved performance and lower operational costs.

Innovative packaging equipment is transforming supply chain dynamics, allowing companies to achieve unprecedented efficiency gains. By utilizing modern packaging practices, businesses can streamline their operations, reduce waste, and respond more rapidly to market demands. Advanced technologies, such as automated packaging lines and smart sensors, enable precise measurement of packaging processes, leading to improved performance and lower operational costs.

Tips for Optimizing Packaging Efficiency:

- Invest in Automation: Implementing automated systems can significantly speed up packaging processes while minimizing human error. Consider integrating robotics for repetitive tasks to enhance overall accuracy and efficiency.

- Utilize Smart Technology: Employ smart sensors and data analytics to monitor packaging operations in real-time. This allows for immediate adjustments and the ability to predict potential bottlenecks before they occur.

The shift to modern packaging not only boosts efficiency but also enhances sustainability efforts. By optimizing packaging sizes and materials, companies can reduce their carbon footprint and improve their overall environmental impact. Adopting these innovative practices within the supply chain fosters a culture of continuous improvement, making businesses more competitive in an ever-evolving marketplace.

Related Posts

-

Emerging Innovations in Food Packaging Equipment for 2025 and Beyond

-

Exploring Sustainable Packaging Equipment Alternatives for Modern Businesses

-

What is Packaging Equipment and How It Transforms Modern Manufacturing

-

Ultimate Checklist for Choosing the Best Filling Equipment for Your Business Needs

-

Future-Proofing Your Supply Chain: Key Innovations in Pouch Packaging by 2025

-

Future of Packing Equipment: 2025 Innovations and How to Optimize Your Supply Chain