ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreTop Vertical Form Fill Seal Machines: Features, Benefits & Buying Guide

In the ever-evolving landscape of packaging technology, the Vertical Form Fill Seal Machine stands out as a pivotal solution for various industries looking to enhance their packaging efficiency. This innovative machine automates the process of forming, filling, and sealing packages, offering a streamlined approach that significantly reduces labor costs and production time. As businesses strive to meet rising consumer demands for quicker and more efficient packaging, understanding the features and benefits of these machines becomes essential for informed purchasing decisions.

The versatility of the Vertical Form Fill Seal Machine is one of its most remarkable attributes. Capable of handling a wide range of products—from dry goods and liquids to granular items—these machines are designed to accommodate diverse packaging needs. Moreover, the integration of advanced technology allows for precise control over the packaging process, ensuring consistent quality and reducing the likelihood of errors. As we delve deeper into the features, benefits, and essential considerations for purchasing a Vertical Form Fill Seal Machine, it becomes clear that this equipment is not just an investment, but a crucial component in optimizing operational efficiency and maintaining competitiveness in the marketplace.

Overview of Vertical Form Fill Seal Machines

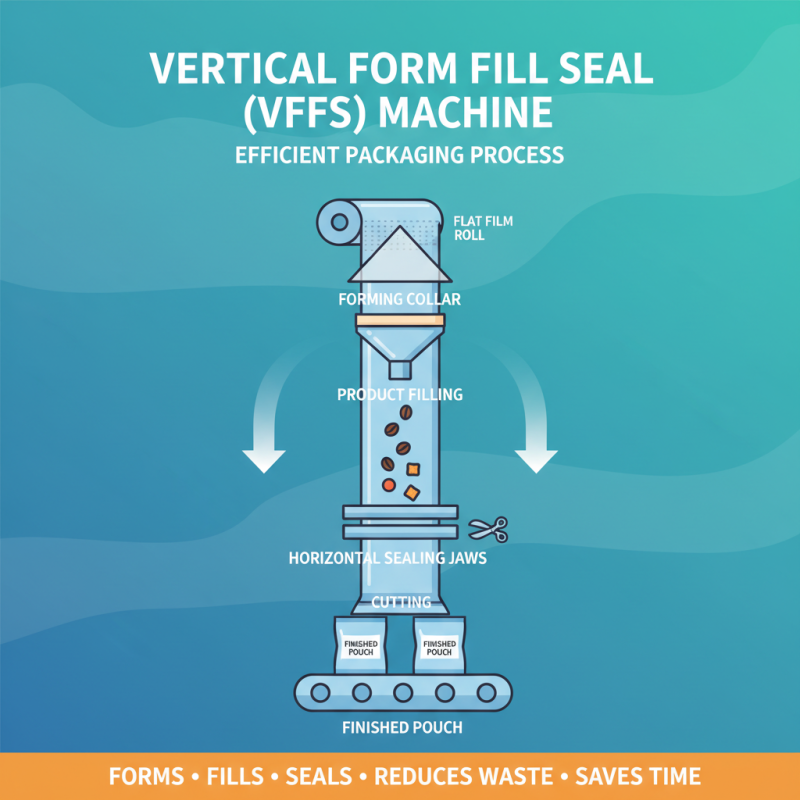

Vertical Form Fill Seal (VFFS) machines are essential in modern packaging processes, providing an efficient solution for filling and sealing products into bags or pouches. These machines operate by forming a flat film into a tube, filling it with the desired product, and then sealing it all in a continuous process. This seamless integration not only reduces packaging time but also minimizes material waste, making VFFS machines a popular choice across various industries.

When considering the purchase of a VFFS machine, it’s important to assess its features, such as speed, ease of use, and adaptability to different package sizes. Additionally, look for machines that offer precise filling capabilities to ensure product consistency and maintain quality. Understanding the product you intend to package will also help you choose a machine equipped to handle specific materials, whether they're dry, liquid, or powder-based.

**Tips:** Always conduct a needs assessment before investing in a VFFS machine. Consider factors such as the expected production volume and the complexity of your packaging requirements. Another key tip is to prioritize machines with user-friendly interfaces to facilitate smooth operation and reduce the learning curve for your staff. Regular maintenance and support options should also be explored to ensure the longevity and optimal performance of the equipment.

Key Features of Vertical Form Fill Seal Machines

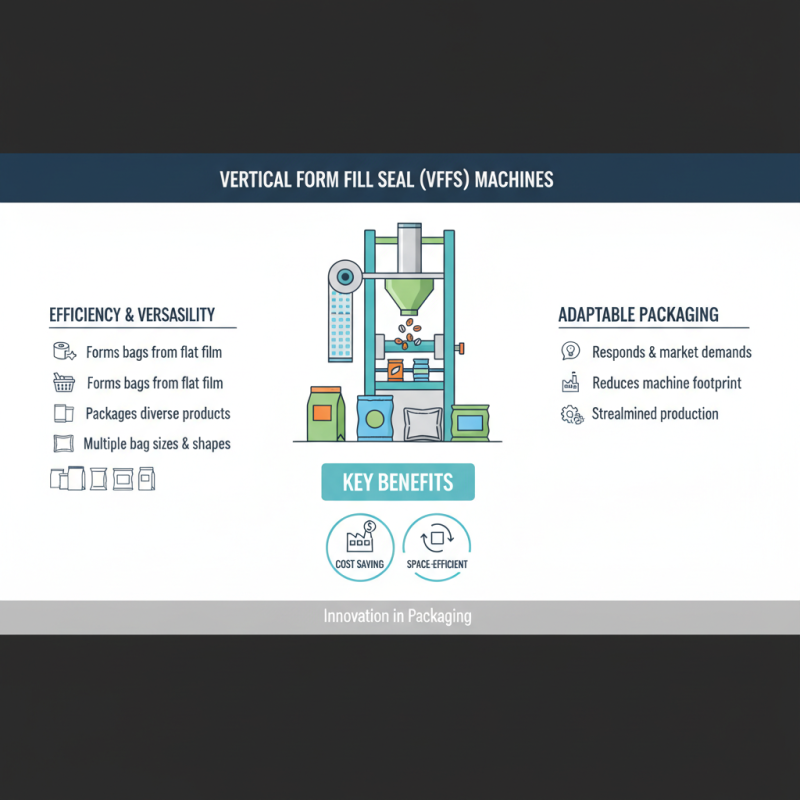

Vertical Form Fill Seal (VFFS) machines are essential in the packaging industry for their efficiency and versatility in packaging a wide range of products. One of the key features of these machines is their ability to create bags of various sizes and shapes from a flat roll of film. This adaptability allows manufacturers to address different market demands without needing multiple machines, ultimately saving space and costs in production lines.

Another significant feature of VFFS machines is their automation capability, which enhances speed and accuracy in the packaging process. By integrating advanced controls and sensors, these machines can ensure precise filling, sealing, and cutting operations, reducing the likelihood of errors and waste. Additionally, many VFFS machines come equipped with adjustable parameters that enable operators to fine-tune their settings according to specific product requirements, including dose size and sealing temperature, which further boosts productivity and flexibility in packaging different products.

The construction of VFFS machines also emphasizes hygienic design, making them suitable for sectors like food and pharmaceuticals. Features such as easy cleanup and maintenance, along with the use of high-quality materials that meet safety standards, ensure that the machines not only operate efficiently but also maintain the integrity of the products being packaged. These characteristics make VFFS machines a valuable investment for businesses looking to enhance their packaging operations.

Advantages of Using Vertical Form Fill Seal Machines

Vertical Form Fill Seal (VFFS) machines present numerous advantages for businesses looking to enhance their packaging processes. One of the primary benefits is the efficiency they offer. By automating the packaging process, VFFS machines can significantly reduce labor costs and increase output. They create bags from a flat roll of film, fill them with product, and seal them—all in one continuous process. This efficiency not only streamlines operations but also minimizes waste, as the machines are designed for precise and accurate filling.

Another notable advantage of using VFFS machines is their versatility. These machines can accommodate a wide range of products, including solids, liquids, and powders, making them suitable for various industries such as food, pharmaceuticals, and personal care. The ability to switch between different bag sizes and styles further enhances their adaptability, allowing businesses to respond quickly to changing market demands.

Tips: When considering a VFFS machine for your packaging needs, evaluate the specific requirements of your product. Factors such as product consistency, moisture sensitivity, and the desired shelf life can all influence the choice of machine features. Additionally, invest in training for your operators to ensure they can maximize the machine’s capabilities and maintain optimal efficiency over time.

Top Vertical Form Fill Seal Machines: Features, Benefits & Buying Guide

| Feature | Description | Benefits | Suitable For |

|---|---|---|---|

| High-Speed Operation | Machines designed for high throughput, capable of producing up to 150 packs per minute. | Increased efficiency and productivity, reducing labor costs. | Food production, pharmaceuticals, and consumer goods. |

| Versatility | Can handle a wide variety of packaging materials and formats. | Flexibility to produce different package types, catering to varied market needs. | Snacks, sauces, powders, and liquids. |

| User-Friendly Interface | Touchscreen controls with easy programming and setup. | Reduces training time for operators and minimizes errors. | Small to medium enterprises looking for ease of use. |

| Compact Design | Space-saving design suitable for limited floor space. | Maximizes operational efficiency without requiring large installations. | Startups and small-sized food manufacturers. |

| Durability | Constructed with high-quality materials for longevity. | Lower replacement costs and reduced downtime. | All industries requiring reliable packaging solutions. |

Factors to Consider When Buying Vertical Form Fill Seal Machines

When considering the purchase of vertical form fill seal (VFFS) machines, several key factors come into play that can significantly influence the efficiency and effectiveness of your packaging operations. One of the foremost considerations is the machine's production speed, measured in bags per minute (BPM). According to the report by Allied Market Research, the VFFS machine market is projected to reach $3.8 billion by 2027, highlighting the increasing demand for faster and more efficient packaging solutions. A machine that can effectively meet your production requirements while minimizing downtime is essential for maintaining productivity.

Another critical factor is the type of materials your VFFS machine can handle. Different machines are designed to work with various films and packaging materials, so understanding the compatibility with your specific products is vital. For instance, flexible, rigid, and biodegradable materials may all require distinct sealing technologies and handling capabilities. Research indicates that the flexible packaging sector is expected to witness substantial growth, which underscores the necessity of investing in a VFFS machine that accommodates the evolving landscape of packaging materials. Additionally, consider machine features such as ease of operation, maintenance requirements, and integration capabilities with existing production lines, all of which play a significant role in streamlining your packaging process.

Top Vertical Form Fill Seal Machines: Performance Comparison

Top Brands and Models of Vertical Form Fill Seal Machines

Vertical form fill seal machines are essential tools in the packaging industry, renowned for their efficiency and versatility. These machines utilize rolls of film to create bags from a flat sheet, filling them with products before sealing them shut. Among the most popular options on the market are continuous and intermittent motion machines, each offering unique advantages depending on production needs. Continuous machines are praised for their speed and efficiency, while intermittent machines provide better flexibility for varied product sizes.

When selecting a vertical form fill seal machine, it's crucial to consider the specific application, the type of products being packaged, and the desired output speed. Key features to look for include easy maintenance, user-friendly controls, and compatibility with various film types. Additionally, machines with advanced sealing technology will ensure better package integrity, which is vital for preserving product freshness.

Tips: Before making a purchase, evaluate how the machine integrates into your existing packing line. Seek models that offer scalability should your production volume increase. Furthermore, always consult user reviews and feedback to gauge reliability and performance based on real-world applications. Investing time in thorough research will ensure you choose a machine that aligns perfectly with your operational requirements.

Related Posts

-

What is Packaging Equipment and How It Transforms Modern Manufacturing

-

Discover Top-Quality Packaging Systems from China's Leading Manufacturing Experts

-

Future of Packing Equipment: 2025 Innovations and How to Optimize Your Supply Chain

-

Revolutionizing Efficiency: How Innovative Packaging Equipment Enhances Supply Chain Performance

-

Exploring Innovative Examples of the Best Case Packing Techniques for Enhanced Efficiency

-

Innovative Examples of Best Packing Equipment for Global Buyers