ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreWhat is a Wire Mesh Weaving Machine and How Does It Work?

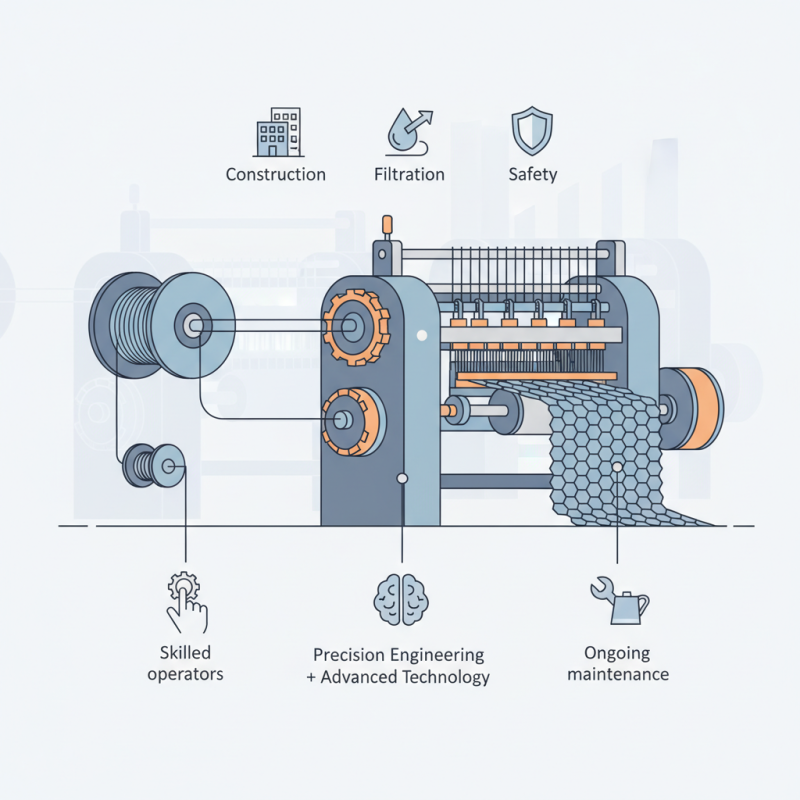

A wire mesh weaving machine is an essential tool in various industries. This device is designed to produce high-quality wire mesh used in construction, filtration, and safety applications. The machine works by weaving strands of wire together in a specific pattern, creating a strong and durable product.

Understanding how a wire mesh weaving machine operates can reveal its importance. It typically combines precision engineering with advanced technology. The machine feeds in rolls of wire, which are then woven through a series of guides and tensioning systems. The end result is a consistent and reliable mesh. Observing this process can spark curiosity and appreciation for the craftsmanship involved.

However, the wire mesh weaving machine is not without its challenges. Variations in wire types and mesh patterns can affect performance. Operators must be skilled to handle these variations efficiently. Although the machine is powerful, it requires ongoing maintenance to function optimally. This balance of innovation and practical issues reflects the complexities present in manufacturing processes today.

What is a Wire Mesh Weaving Machine?

A wire mesh weaving machine is a specialized tool used in construction and manufacturing. It creates various types of wire mesh, which have critical applications in multiple industries. The machine typically utilizes fine wires and weaves them into a grid format. This mesh can be made from different materials like stainless steel or galvanized wire.

Production data indicates that the global wire mesh market is expected to reach USD 5 billion by 2025. This growth reflects the rising demands from the construction and automotive sectors. A wire mesh weaving machine operates by interlacing wires through a series of precise movements. These machines can adjust wire spacing and tension, allowing for customizable outputs.

While this technology is beneficial, it is essential to consider its limitations. The setup of these machines can be complex, requiring a skilled operator. Also, production speed may vary based on material thickness. Adjustments often take time, which can reduce overall efficiency. Therefore, continuous training and development in this field are crucial for improving operations and responsiveness to market demands.

What is a Wire Mesh Weaving Machine and How Does It Work?

| Feature | Description | Functionality | Common Applications |

|---|---|---|---|

| Machine Type | Automatic and Semi-Automatic | Enables rapid production | Construction, Agriculture |

| Material Used | Metal Wire | Durability and strength | Fences, Screens |

| Weaving Patterns | Plain, Twill, Custom | Versatile design options | Industrial, Decorative |

| Production Speed | High Speed (Meters per Minute) | Efficient mass production | Manufacturing, Packaging |

| Control System | PLC-Based Automation | Precision and consistency | Automated Environments |

Types of Wire Mesh Weaving Machines

Wire mesh weaving machines come in various types, each designed for specific applications. There are manual and automatic machines. Manual machines require skilled labor to operate effectively. They are often more affordable but can be slower. Automatic machines, however, increase efficiency and reduce labor costs. They excel in high-volume production, making them popular in industrial settings.

Some machines produce welded wire mesh, where wires are fused at intersections. This type creates a strong, durable product. Other machines focus on woven wire mesh, which retains flexibility. Woven mesh has diverse uses, from construction to agriculture. Different materials, like stainless steel and galvanized wire, can be used depending on the intended application.

Selecting the right machine can be challenging. Consider the specific needs and production volume. Each type has distinct advantages and drawbacks. A thorough analysis is essential. While automatic machines save time, they might involve higher upfront costs. Manual machines allow for adjustments but may lack speed. Understanding these factors can lead to better decision-making in the long run.

Wire Mesh Weaving Machine Production by Type (2022)

Key Components of Wire Mesh Weaving Machines

Wire mesh weaving machines are crucial in manufacturing various types of mesh products. These machines consist of several key components that ensure effective operation. The primary parts include the weft and warp systems, shuttle mechanisms, and control panels. Each component plays a significant role in the weaving process.

The warp system holds the vertical wires in place. It determines the mesh’s tension and spacing. Proper tension is essential. According to a 2022 industry report, optimal tension can increase productivity by 15%. The weft system, on the other hand, introduces horizontal wires. It moves quickly and efficiently to create the desired weave pattern. If this system is misaligned, however, it can lead to material waste.

The shuttle mechanism transfers the weft through the warp. Its design influences both speed and accuracy. Some machines now utilize automated shuttles, reducing human error. Yet, even automation can lead to unexpected issues, such as mechanical wear. Control panels allow operators to adjust settings easily. It’s not uncommon for users to face challenges when programming complex patterns. These components work together, but maintaining them requires ongoing reflection and adjustment. Regular maintenance plays a vital role in keeping machines operational. Data from the 2023 Manufacturing Insights report indicates that neglected machines can decrease output by 25%.

The Weaving Process: Step-by-Step Overview

The weaving process of a wire mesh weaving machine involves multiple steps. Initially, raw wire coils are fed into the machine. These coils are then unraveled and straightened. This preparation ensures uniformity for the weaving stage. The machine uses a series of rollers to guide the wire smoothly through its components.

Once the wire is straightened, it moves to the weaving area. Here, it intertwines with other wires in a specific pattern to create a sturdy mesh. Operators must adjust various settings throughout this process. Even minor misalignments can lead to undesired outcomes. Regular monitoring is essential, as a small error might impact the final product.

Finally, the completed wire mesh is cut to size. It is then inspected for quality and integrity. Some imperfections may go unnoticed during production. It's crucial for manufacturers to reflect on their processes to ensure that the final mesh meets the required standards. Continuous improvement in technology and techniques can lead to better results.

Applications of Wire Mesh Products in Various Industries

Wire mesh products are prevalent across many industries. Their versatility makes them invaluable in construction, agriculture, and manufacturing. In construction, wire mesh is used for reinforcing concrete. It enhances structural integrity and durability. According to industry reports, concrete reinforced with wire mesh can increase tensile strength by up to 50%. This is significant for infrastructure projects that demand resilience.

In agriculture, wire mesh plays a vital role too. It is often used in fencing and pest control. Durable wire mesh can keep livestock secure and prevent crop damage from animals. Research indicates that farms utilizing wire mesh fencing report a 20% reduction in crop loss. This directly impacts yield and profit margins. The food industry also relies on wire mesh for filtration applications. In processing plants, wire mesh screens provide efficient separation of materials, optimizing production.

Manufacturers are continually exploring new applications for wire mesh. However, challenges remain. Not all wire mesh is created equal. Quality varies significantly within the market. Low-grade options may lead to unexpected failures. This can create safety risks or financial losses. A careful selection process is essential. Understanding material specifications can prevent these issues.